info@shxvalve.com

info@shxvalve.com info@shxvalve.com

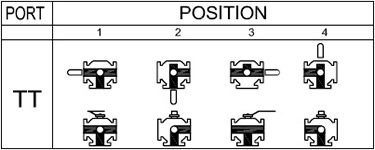

info@shxvalve.com5 way ball valve is known as two-way five-port rotary valve, one valve can be a valve to achieve positive and negative water supply switch, every turn 90℃, water supply mode switch once, before the need for five valves.

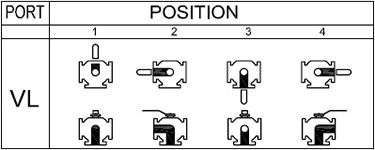

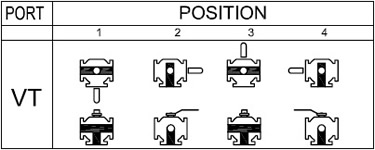

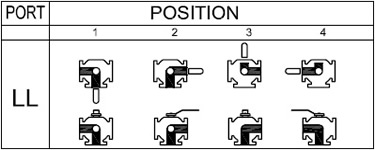

5 way ball valve includes a 5 port valve body and a ball, and adopts a spherical spool, and uses a spherical sealing ring to ensure the sealing performance between the valve body and the spool. The spool and the valve sleeve need to be connected by a compression spring to ensure the tightness of the connection between the spool and the valve sleeve. 5 way ball valve body is provided with radial valve holes in five different directions, the sealing ring is arranged between the spool and the valve hole, the spool is a ball, the center of the ball is connected with the rotating shaft, the sealing ring includes a spherical sealing ring and a plane sealing ring, the plane sealing ring is arranged in the connection of the axial plane of the spool and the valve hole, the spherical sealing ring is arranged in the connection of the radial plane of the spool and the valve hole. When different valve holes are connected, the valve holes are round, and the diameter of the channel between the ball spool and the valve body is the same, so that the proportion of the channel inside the valve hole is all connected, and there will be no turbulent rubbing phenomenon, reducing the corrosion of the valve core. The composite sealing device adopts spherical sealing ring and surface sealing ring, and the sealing ring conforms to the shape of the connecting surface of the valve body and the valve core to improve the sealing property.

| Product Name | 5 way ball valve |

| 1. Material | WCB,SS304/316/304L/316L ( CF8/CF8M/CF3/CF3M),etc. |

| 2. Size | 1/2~12 inch ( DN15~DN300) |

| 3. Port | 5 way Port |

| 4. Working Pressure | 150LB~600LB |

| 5. Connection Ends | Flange,threaded end or others |

| 6. Working Temp. | -29~180℃,-40~450℃ or according to customer requirements for different industry. |

| 7. Suitable Medium | Water, Natural Gas, Oil and some corrosive liquid |

| 8. Operation | Handle operated, Locking device is option |

| 9. Inspection & Testing | According to API598,JB/T9092 |

1. Small fluid resistance: 5 way ball valve ball and valve body connecting the pipe section is equal, and the ball channel is connected by an arc, the medium through the ball, fluid resistance is small.

2. Good sealing performance: 5 way ball valve seat is made of PTFE material with certain elastic deformation and high strength to achieve good sealing performance and ensure the stability of the valve.

3. Long service life: stainless steel is used for the valve core and bare neck, PTFE is used for the valve seat, which can achieve good corrosion resistance and extend the service life of the valve.

5 way ball valves can be used in oil, natural gas, coal and ore mining, refining and processing and pipeline transportation system;

In the production of chemical products, medicine and food;In hydroelectric, thermal and nuclear power generation systems;

In the water and drainage, heating and gas supply systems of urban and industrial enterprises;

In the drainage and irrigation system of farmland;

5 way ball valve is an important mechanical product closely related to production construction, national defense construction and people's life.

5 way ball valve is used in all kinds of pipeline systems to cut off or connect the medium flow, so that the medium is transported to each designated point in accordance with a predetermined program.